ZHEJIANG WEIGANG TECHNOLOGY CO., LTD showcases advanced printing solutions at booth C40

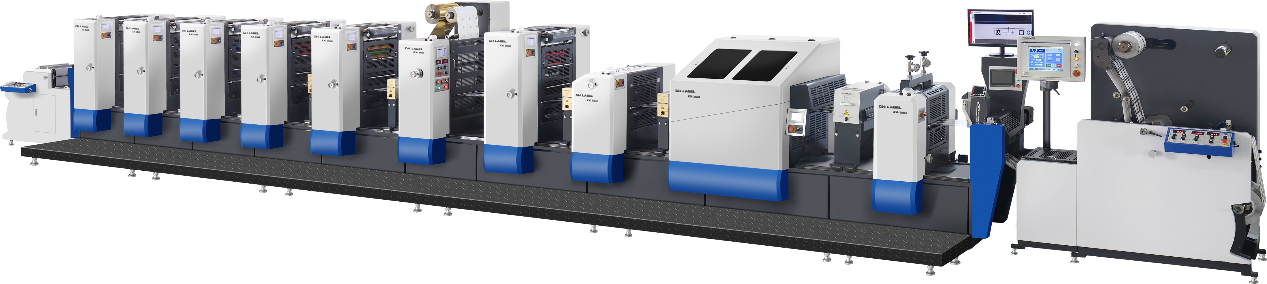

1. ZX-320/450 Intermittent PS Plate Label Printing Press (Offset)

This machine's entire control system adopts the latest microcomputer servo control and operating systems from renowned foreign manufacturers. It features stable and accurate material feeding, requires no impression cylinder changes, and offers fast, convenient, and simple operation. Utilizing PS plate intermittent printing, it is highly suitable for printing both small and large batches of high-end labels, making it the ideal model for printing premium self-adhesive labels.

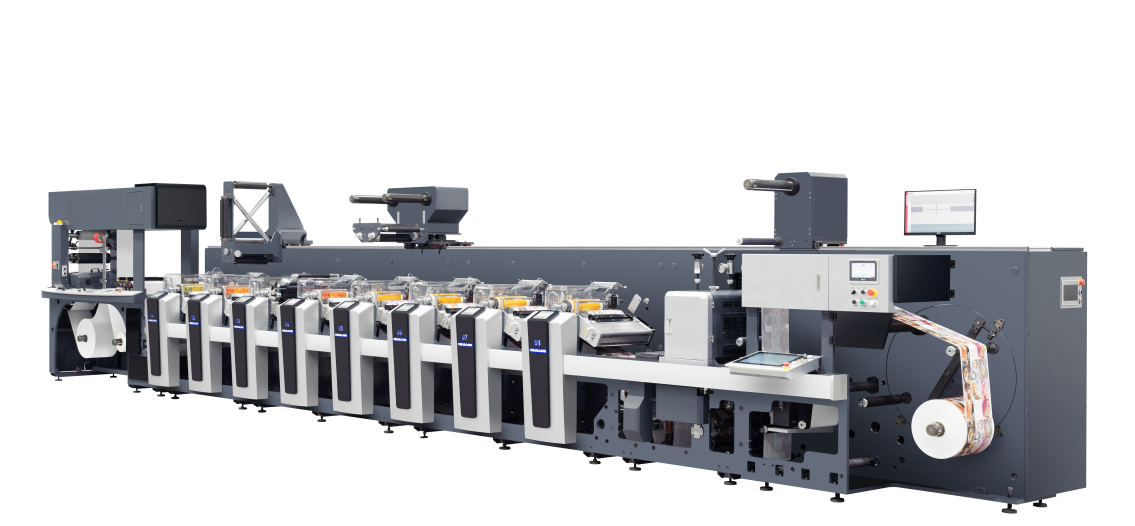

2. ZJR-350E Unit-Type Flexographic Printing Press

- The entire machine control system uses the latest microcomputer servo control and operating system. Each printing unit is driven by an independent servo motor (22 servo motors total for an 8-color, 3-die-cutting station configuration), ensuring high-precision registration during high-speed operation.

- The plate cylinder uses an air-expansion sleeve type design. The plate cylinder is lightweight and does not require gears, enabling quick, convenient, and simple plate cylinder changes. The absence of gears on the plate cylinder improves print quality and reduces maintenance.

- Printing and ink transfer pressure adjustment: The plate cylinder uses a shoulder support method. Adjusting printing pressure and ink transfer pressure involves fine-tuning the corresponding support frames on both sides. Changing plate cylinder sizes requires no major pressure adjustments, and even special printing needs only require minor fine-tuning, significantly improving printing efficiency (previous structures required re-adjusting pressures for each job, wasting time and materials).

- The impression cylinder is equipped with a water cooling device, preventing high temperatures generated by UV curing from affecting the printing of film materials.

- This machine is suitable for printing on materials such as paper and laminates (PET, OPP, CPP, PP).

3. WG S230 Elegant Series Digital Printing Press

- Flexible color configuration, allowing random combination of colors and enhancement solutions.

- Maximum printing speed of 60 m/min, balancing high efficiency and job flexibility.

- Printing width of 230mm, broadening customer application scope and increasing flexibility.

- Utilizes a single-pass solution, non-contact printing, finished in one pass, no plate making required.

- Maximum print resolution of 1200*600 DPI, with other modes available (900*600, 600*600). Delicate imaging and rich colors.

- Highly integrated software enables quick order acceptance, small batch customization, proofing, and other functions.

- Simple and user-friendly human-machine interface (HMI) for quick onboarding.

- Moisturizing and printhead crash prevention facilitate easy maintenance.

- Compact size, small footprint, adaptable to various application scenarios.

- Equipped with high-precision piezoelectric printheads, durable and long-lasting.

- Consistent print quality, supports 24/7 production.

4.WG S350 Ultra Series Digital Printing Press

- Flexible color configuration, allowing任意 combination of colors and enhancement solutions.

- Maximum printing speed of 60 m/min, balancing high efficiency and job flexibility.

- Printing width of 350mm, broadening customer application scope and increasing flexibility.

- Equipped with high-precision piezoelectric printheads, durable and long-lasting.

- Consistent print quality, supports 24/7 production.

- Utilizes a single-pass solution, non-contact printing, finished in one pass, no plate making required.

- Maximum print resolution of 1200*600 DPI, with other modes available (900*600, 600*600). Delicate imaging and饱满 colors.

- CMYK + spot color reproduction for rich colors; white ink and varnish provide enhancement effects.

- Highly integrated software enables quick order acceptance, small batch customization, proofing, and other functions.

- Simple and user-friendly human-machine interface (HMI) for quick onboarding.

- Automatic cleaning, moisturizing, and printhead crash prevention facilitate easy maintenance.

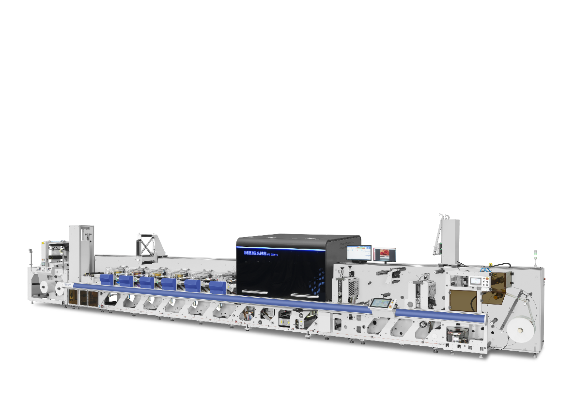

5.ZJR S350 PRO Series Digital Flexo Hybrid Printing Press

- The entire machine control system uses the latest microcomputer servo control and operating system. Each printing unit is driven by an independent servo motor, ensuring high-precision registration during high-speed operation.

- The plate cylinder uses an air-expansion sleeve type design. The plate cylinder is lightweight and does not require gears, enabling quick, convenient, and simple cylinder changes. The absence of gears improves print quality and reduces maintenance.

- Printing and ink transfer pressure adjustment: The plate cylinder uses a shoulder support method. Adjusting printing pressure and ink transfer pressure involves fine-tuning the corresponding support frames on both sides. Changing plate cylinder sizes requires no major pressure adjustments, and even special printing needs only require minor fine-tuning, significantly improving printing efficiency.

- The printing unit is equipped with a water-cooled roller cooling device, preventing high temperatures generated by UV curing from affecting the printing of film materials.

- This machine is suitable for printing on materials such as paper and laminates (PET, OPP, CPP, PP).

- Utilizes high-precision piezoelectric printheads, with multiple print resolution modes available (1200*600, 900*600, 600*600).

- Employs a single-pass solution, non-contact printing.

- CMYK four colors + enhancement + white ink mode (optional).

- Automatic cleaning, moisturizing, and printhead crash prevention facilitate easy maintenance.

- Supports high-speed variable data printing.

The unit-type flexo plus digital six-color printing press effectively addresses flexo customers' needs for digital variable data applications, meeting their requirements for short digital runs and proofing.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

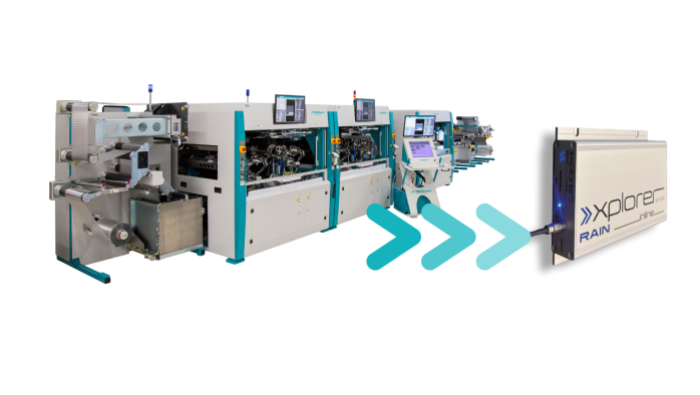

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show