Cutting-edge label printing and digital embellishment solutions at stand F18 by Label Source & Hanlabel

- New!1200 DPI high-speed label combination printer LabStar 330HD Hybrid

Maximum resolution: 1200DPI

Printing ink consumption: 1200 × 600, 1200 × 900, 1200 × 1200

Maximum printing speed: 80~120m/min

Maximum printing width: 322 mm

Multiple options, flexible combination as required: 8-color digital, multi-color group flexographic printing, embossed printing, gilding, adhesive printing, film covering, lamination, die cutting, waste removal, non-stop winding and unwinding, automatic avoidance function of over-joint, online digital efficiency, etc.

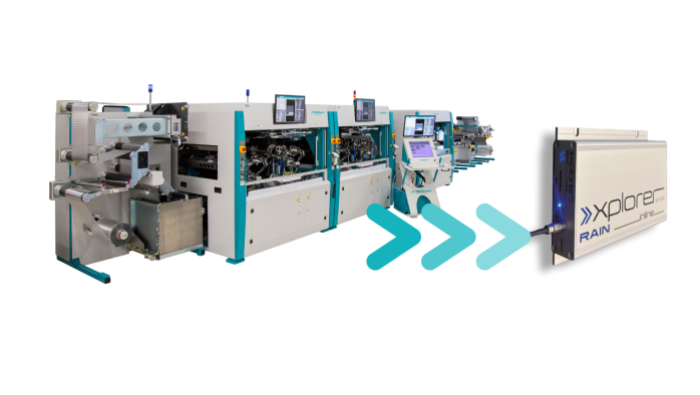

Multiple combination scheme of "digital+flexo": from material unwinding, printing and efficiency improvement to finished product cutting and winding, integrate the end-to-end label production linkage line, perfectly combine the multi-process label products, and automatically and efficiently produce the linkage line, which can save labor and meet the one-time molding of various process labels.

Core advantages of the scheme:

- Full-process automatic production, one-time molding of multi-process labels

- Production efficiency upgrading, full resolution of 80-170 m/min

- Single Pass, 1200 DPI technology strong drive

- Multi-color flexible combination scheme, upgrading 8-color digital scheme

- Wide color range, multiple process combination, butterfly is infinitely possible

- Realize multi-layered label, transfer label, anti-counterfeiting label and other rich applications

- Closed-loop digital workflow with efficient linear output

- Integrated control platform, intelligent and simple operation

- A new generation of digital post-printing machine

Richo 4800×1200dpi industrial-grade piezoelectric sprayer is adopted, and the control system independently designed by HanGlory Group is matched to realize precise ink control, so that the thickness of light oil can reach 0.3mm, and the light oil effect comparable to that of screen printing can be achieved; At the same time, it has hot and cold ironing two printing methods, which can perfectly present the synergistic effect of 0.05 mm fine lines and fine text.

The equipment also integrates multiple practical functions: support multi-group ink box ink switching and automatic cleaning of ink path; equipped with sprinkler automatic cleaning, moisturizing and waste ink automatic recycling system, which can further improve the quality of light oil and gilding and guarantee efficiency; In addition, it can run online with the printing equipment, with the maximum speed of 72m/min. It can realize digital hot ironing, cold ironing and light oil efficiency improvement at the same time. The post-printing efficiency improvement process is upgraded to 2.0 version through superfine light oil jet printing and hot ironing technology.

- Inline type digital embellishment machine

Highly automated, simple machine operation, high production efficiency and good printing effect

Special functions: non-stop unwinding, 10-color flexographic printing, shift cold ironing, film covering/cold ironing, adhesive printing, multi-layer label, non-stop winding, non-stop waste removal, automatic visual registration, hot ironing, efficiency improvement, etc.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show