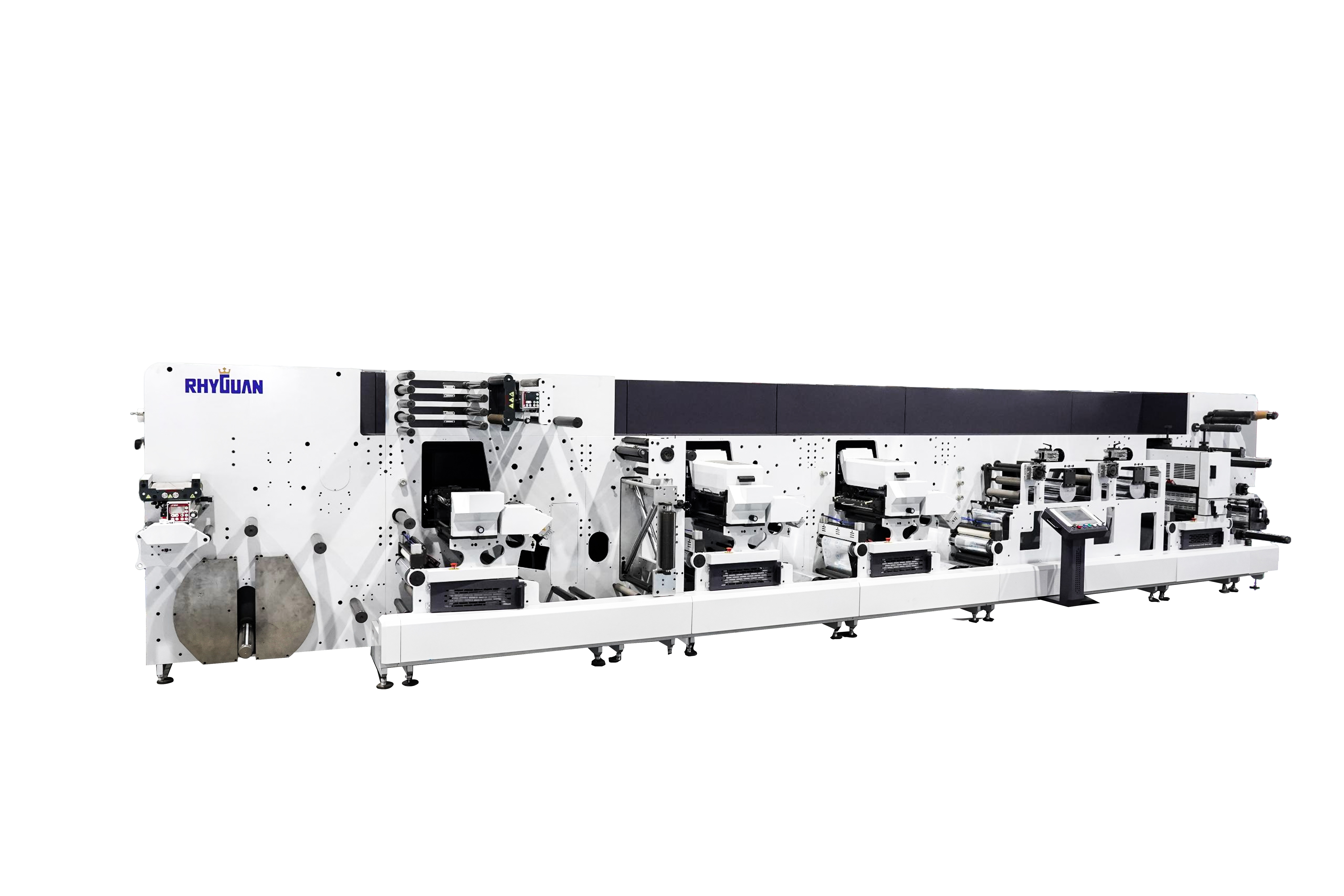

RHYGUAN RF-330 Flexographic press to make Asian debut at Labelexpo Asia 2025

Exhibits

- New! RF-330 Semi/Full Rotary Flexo Printing Machine

The RF-330 flexo press features a revolutionary full-rotary design and exceptional cost-effectiveness. Servo-driven and versatile, it supports both full-rotary (180 m/min) and intermittent (60 m/min) operation modes with a 330 mm printing width—ideal for proofing and short-run production.

- Lowers overall cost: Single-cylinder/small-plate design reduces plate-making expense.

- Multi-process integration: Handles multi-layer overprinting, eliminating need for separate screen printing units.

- Reduces foil waste: Step-and-repeat cold foiling maximizes material utilization.

- Boosts die-cutting efficiency: Reaches 90 m/min in semi-rotary mode without cylinder changes

2. PULS-330 Modular Digital Finishing Machine

The PULS-330 modular digital finishing system from Zhejiang Rhyguan represents the pinnacle of integrated technology in label production. It functions not as a single-purpose printer, but as a fully automated "intelligent production unit" that transforms raw materials into finished multi-layer labels in one continuous process. This innovation fundamentally reshapes traditional multi-equipment, multi-step workflows, delivering unmatched competitive advantages.

From Printing to Finished Product: All-in-One Revolution

The system seamlessly integrates all key processes—including flexo printing, delam/relam, backside treatment, precision lamination, die-cutting, and slitting—into a single production line. Roll materials enter one end, and fully finished, ready-to-ship labels are produced at the other.

Core Technologies: Precision and Reliability

- High-precision tension control ensures perfect layer-to-layer registration during lamination, printing, and die-cutting, eliminating misalignment and reducing waste.

- It supports both full-rotary mode for high-speed continuous printing and intermittent mode for precise printing in specific areas (e.g., coding, variable data).

- An integrated die-cutting station performs precision rotary or flatbed die-cutting in one pass, with optional slitting for multiple narrow rolls or sheets, saving significant post-production time and cost.

- One-touch operation enables a single operator to monitor the entire line, reducing labor dependency and management complexity.

- The system rapidly adapts to small-batch, high-mix, and complex orders, helping printers capture opportunities in a fast-moving market.

3. Exhibition Machine: PLUS-330 Digital Embellishment System

The PLUS-330 is an advanced finishing system engineered to enhance both product value and production efficiency. It integrates multiple key processes—including flexo coating, hot foiling, digital embellishment, rotary die-cutting, and automatic slitting—into a single compact platform. This all-in-one design streamlines the workflow from semi-finished labels to high-value finished products.

Its core strengths lie in flexibility and value-adding capability:

- Applies varnish with various effects (gloss, matte, tactile)

- Performs diverse hot foil stamping for premium labels

- Adds variable data, graphics, or effects via digital embellishment

- Ensures precision with servo-driven die-cutting and slitting

The system reduces manual intervention, shortens changeover time, and minimizes material waste. Ideal for short runs and fast-changing orders, the PLUS-330 helps label converters boost competitiveness while cutting costs and lead times.

4. New Generation High-Speed Rotary Die-cutting Unit

The new generation high-speed rotary die-cutting unit adopts an innovative dual-anvil-roller adjustable working mechanism. This groundbreaking design elevates maximum production speed to 150 m/min while significantly minimizing downtime, resulting in a substantial leap in overall equipment efficiency.

Surpassing conventional rotary die-cutting systems, it delivers sustained and stable operation at ultra-high speeds, positioning it as an industry benchmark for performance. This enables customers to achieve a crucial time-to-market advantage.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

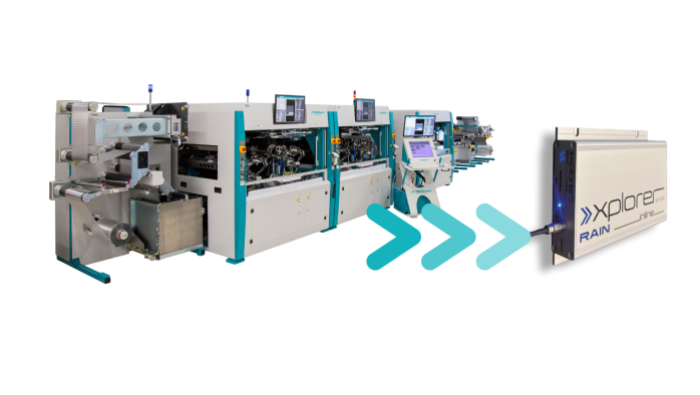

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show