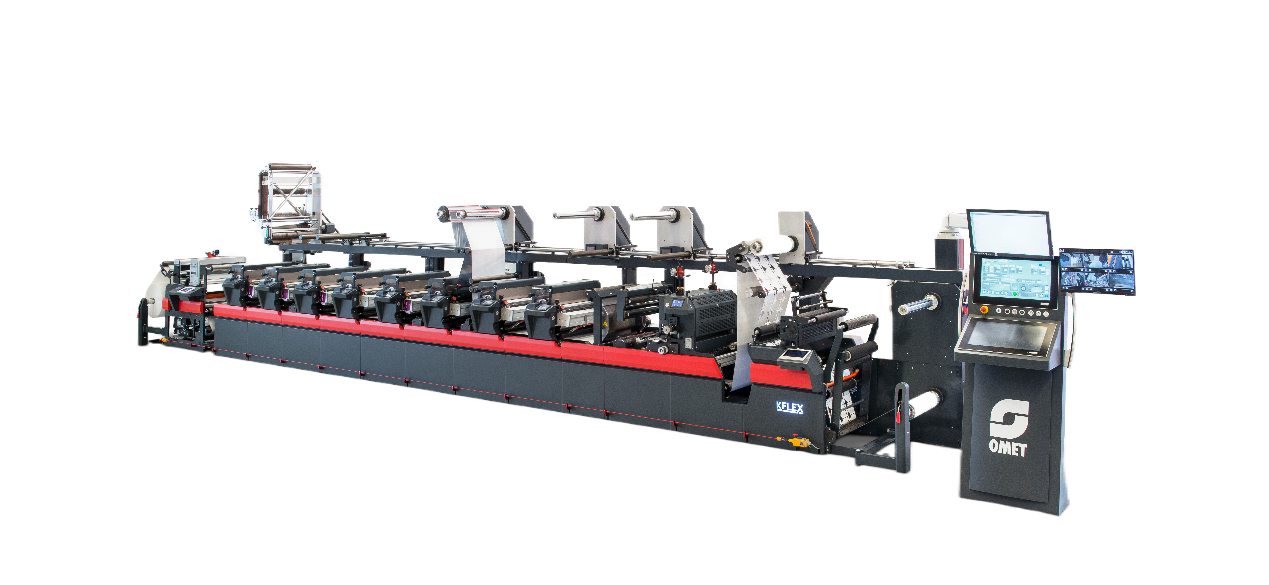

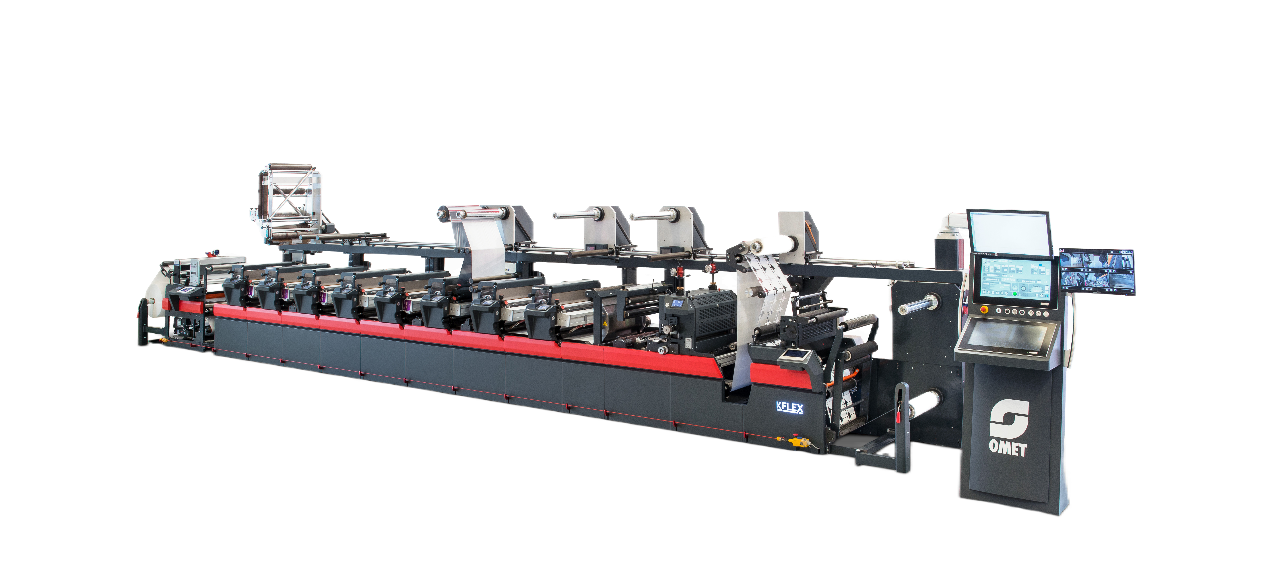

Omet will highlight the KFLEX high-precision flexographic press at Labelexpo Asia 2025

Exhibit:

KFLEX high precision flexo press

(This device will not be physically displayed on site; the focus will be solely on its promotion.)

60 years of experience have inspired the high-precision flexo press KFLEX, maintaining a highly modular design and high flexibility. OMET KFlex combines unprecedented flexibility with state-of-the-art technology to provide maximum performance and outstanding printing quality. The revolutionary SWITCH system allows every printer to adapt the press configuration to all production needs, today and in the future, providing always a solution in terms of productivity and quality.

- Independent servo drive of impression roll and plate cylinder

- Available of double pass, reverse printing without web turn bar, effectively avoid material scratching

- Removable flexo printing head, for maintenance and repair offline

- The tension control roller can be installed between the print units, which can print light cardboard, lamitube and other special materials, with wider printing range

- "V" type ink tank is selected for short order production, and 10L ink bucket is used for long order production

- Online cleaning of dirty spots on the plate, with no downtime of the machine

- Inheriting the "On the fly" instant pre-register system configured on models above Omet X6, with photocell reading the master mark, and servo-driven plate cylinder gets aligned in real-time, no need to set web path and independently from the skills of the operator.

- Vision-1 automatic register system, with real time alignment of both vertical and horizontal directions, and independent of operator’s skills

- Interchangeability between print and die-cut units through easy and quick handling operations, meeting the needs of special label production.

- The Easy-Change Die-Cutting system, thanks to its sliding system, all tools can be changed easily and quickly with no need for any lifting device.

- Long hot air drying unit, can be installed 2 hot air bellows, used for water-based high covering white primer or large area printing, running speed up to 120m/min.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

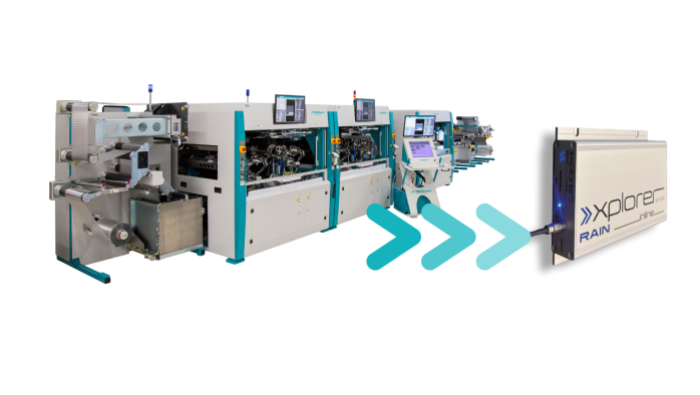

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show