Shenzhen Huada Huahui Machinery Co. Ltd at booth: M30

- PS Plate Roll to Roll Offset Printing Machine HDPS-450

The HDPS-450 (Model: HDPS-450-6) is a high-performance PS-based web-fed offset press designed for roll-to-roll printing. It supports maximum unwinding and rewinding diameters of 700mm, a web width of 460mm, and a maximum printing width of 440mm. The printing length ranges from 185mm to 390mm, accommodating material thicknesses between 0.1mm and 0.3mm. The machine operates at speeds ranging from 50 to 200 revolutions per minute (approximately 50 meters per minute).

The standard configuration includes: six printing units, an automatic ink washing system, an alcohol dampening chiller, a punching machine, six rubber rollers, and six dampening rollers. It is also equipped with six LED UV curing systems in a 1+4+1 layout, a paper feeder, a transformer, a static vision system (still-image inspector), and a standard delivery unit. A set of standard tools is provided to ensure comprehensive printing functionality and stable production performance.

2. PS Plate Roll to Roll Offset Printing Machine HDPS-350

The HDPS-350 is a high-performance PS-based web-fed offset press designed for roll-to-roll printing. It supports a maximum unwinding/rewinding diameter of 700 mm, a web width of 350 mm, and a maximum printing width of 340 mm. The printable length ranges from 175 to 350 mm, and it can process materials with thicknesses between 0.1–0.3 mm. The machine operates at speeds from 50 to 200 revolutions per minute (approximately 50 meters per minute).

The standard configuration includes: six printing units, an automatic ink washing system, an alcohol dampening chiller, a punching unit, six rubber rollers and dampening rollers, six LED UV curing systems in a 1+4+1 layout, a paper feeder, a transformer, a static vision system (still-image inspector), and a standard delivery unit. A set of standard tools is also provided to ensure reliable operation and high-quality printing performance.

3. Letterpress Intermittent Rotary Printing Machine HD-300

This model features a compact structure and flexible operation, making it particularly suitable for small to medium runs of self-adhesive label printing. With a maximum web width of 350 mm and a production speed of up to 20,000 sheets per hour, it accommodates material thicknesses ranging from 0.1 to 0.3 mm and supports a maximum unwinding diameter of 700 mm. The press offers both full rotary and intermittent printing modes, adapting to diverse business needs. Standard equipment includes 12 plate cylinders, UV rubber rollers, and an automatic web guide tension system, enabling high-quality printing and rapid job changeovers.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

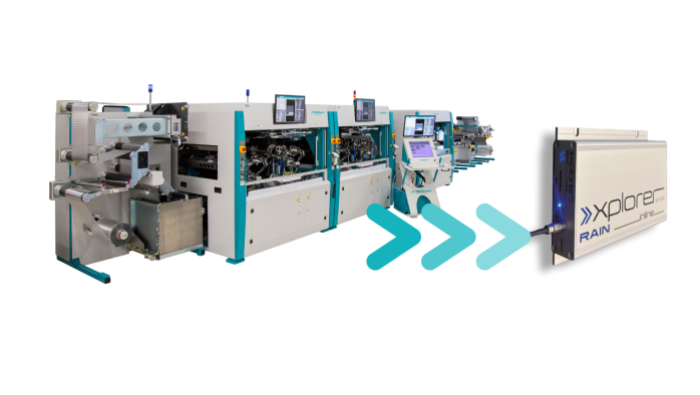

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show