Qianrun Technology will showcase its one-stop flexographic printing solution at booth M35 in Hall E3

As a leading printing equipment manufacturer in China, Qianrun Technology will showcase a range of flexographic printing machines and innovative technologies at booth M35 in Hall E3. Qianrun will demonstrate its latest achievements in high-precision, high-efficiency, and environmentally friendly printing equipment to global customers.

Unit type flexographic printing machine S5-370

The unit-type flexo printing machine adopts a new petal structure and blade system, effectively addressing common drawbacks of conventional flexo printers:

1. It resolves issues such as ink misting (flying ink), "meteor shower" defects, as well as ink overflow and splashing at the edges of the anilox roller during high-speed operation.

2. With an ink consumption as low as a "disposable cup" per startup, it significantly reduces ink waste and cost for printing plants. This innovation enhances operational flexibility and efficiency for print shops.

- Unit type flexographic printing machine S6-450

Equipment Features:

1. Shaftless transmission: Driven by independent dual servo motors, it supports online automatic pre-registration and follow-up registration, ensuring simple and precise calibration.

2. High-efficiency plate cylinder: Features a petal-shaped structure for quick plate changes without major adjustments and eliminates ink streaks. Equipped with a combined UV/LED-UV curing system and a water-cooled impression cylinder.

3. Intelligent non-stop system: An optional non-stop unwind/rewind system supports manual/automatic splicing to enhance productivity. The full-vision automatic registration system enables automatic printing, data storage, and one-touch recall for repeat jobs with auto-registration.

4. Versatile printing capabilities: Primarily designed for flexographic printing, it also supports cold foil stamping, laminating, delamination, multi-layer labels, foldable labels, online quality inspection, and die-cutting. Optional inline functions include screen printing, inkjet coding, and gravure printing.

5. Efficient material handling: An independent roll lifting mechanism with automated control minimizes labor intensity.

- Flexo Logistics Label press

This series are specially design and developed for printing the logistic label, This machine has beautiful appearance and easy operation, and buildup with second web path on top of the machine with the sliding rail, on any Flexo print station can be use for lamination, if equip with butt Splice, non-stop waste remover and fan folding unit, can be perfectly run the production up to 120m/min of the 3 layers logistic label.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

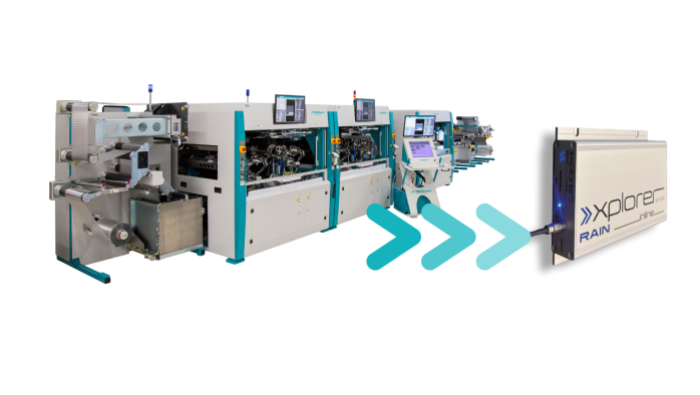

The New RIFD production standard at the Labelexpo Asia 2025

- Review exhibitor list

- Register yourself

- Attend the show